Lift Maintenance Repair Specialists: Prolong the Life of Your Lifts

Wiki Article

Opening the Keys to Reliable Lift Services: Expert Insights Revealed

In the realm of lift repair and upkeep, uncovering the techniques that lead to effective and effective service is comparable to deciphering a complicated puzzle. As we begin on this journey to demystify the secrets behind structured lift repair work, a globe of possibilities arises, promising a future where downtime is minimized, safety and security is prioritized, and functional excellence ends up being the standard.Common Lift Repair Service Obstacles

An additional widespread difficulty in lift repair services is the lack of appropriate upkeep records. Without accurate maintenance documents, fixing specialists may have a hard time to identify issues effectively or anticipate possible troubles. This can result in longer repair times and raised prices as service technicians work to troubleshoot concerns without historic information to assist them.

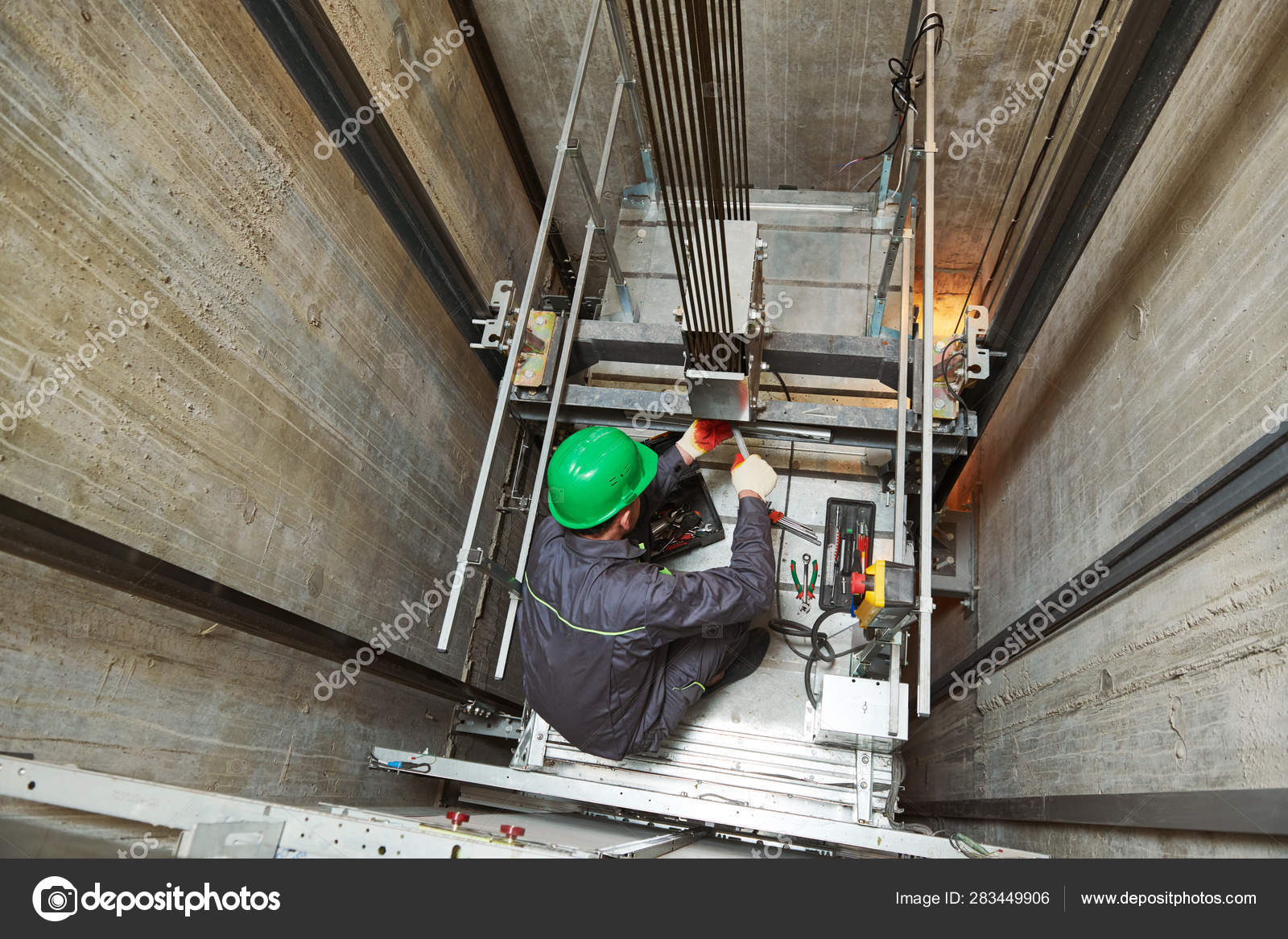

Additionally, ease of access issues within lift shafts can posture considerable difficulties throughout fixings. Limited space, unpleasant angles, and complicated machinery can make it hard for service technicians to get to the required components for repair, lengthening the general repair procedure - Lift Maintenance Repair. By addressing these usual difficulties proactively, lift fixing experts can enhance functional performance and make certain the smooth functioning of upright transportation systems

Proactive Upkeep Strategies

Carrying out proactive maintenance methods is paramount for making certain the longevity and optimum performance of lift systems. By embracing an aggressive strategy to maintenance, structure supervisors and lift maintenance groups can address prospective concerns before they rise into expensive repairs or downtime. One efficient approach is to establish a routine maintenance schedule that includes thorough assessments, lubrication of relocating components, and testing of safety and security attributes.

Moreover, purchasing training programs for upkeep personnel can improve their skills in determining prospective problems and doing preventative upkeep tasks efficiently - Lift Maintenance Repair. By equipping maintenance teams with the understanding and tools needed to proactively maintain lift systems, structure proprietors can decrease disturbances, expand the life expectancy of their lifts, and make sure a secure and trusted upright transportation experience for occupants

Troubleshooting Strategies

Reliable troubleshooting strategies are vital for quickly determining and dealing with concerns with lift systems to reduce downtime and make certain optimal efficiency. One effective method is to start with a thorough visual inspection of the lift parts, inspecting for any kind of visible indicators of wear, imbalance, or damage.

Enhancing Repair Work Abilities

Enhancing effectiveness in lift system fixings is an essential element of ensuring optimum capability and lessening operational disturbances. Lift service technicians should continually work with refining their repair work skills to fulfill the needs have a peek at this site of modern lift systems. One vital method for enhancing fixing skills is regular training sessions that concentrate on both theoretical expertise and useful application. These sessions can cover a variety of subjects such as new modern technologies in the market, troubleshooting intricate issues, and safety and security protocols. Additionally, technicians can gain from hands-on experience under the guidance of experienced professionals to enhance their problem-solving capabilities and decision-making abilities in real-time repair scenarios.Furthermore, staying updated with the most recent innovations in lift technology is vital for technicians wanting to improve their fixing skills. This includes proactively inquiring regarding brand-new parts, software program updates, and maintenance techniques to efficiently identify and remedy concerns. By spending time and initiative into continuous knowing and useful experience, elevator service technicians can dramatically boost their repair competencies and contribute to the efficient functioning of lift systems.

Elevating Maintenance Standards

Boosting upkeep criteria in lift systems is extremely important for making certain long term functional performance and safety and security. Routine maintenance not only enhances the performance of lift systems but additionally decreases the threat of unexpected breakdowns and makes certain the safety and security of customers. By sticking to rigorous upkeep procedures, lift owners and drivers can dramatically lower the probability of expensive repair work and downtime.Implementing a comprehensive upkeep routine that includes normal assessments, lubrication of moving components, and proactive substitute of worn parts is vital. Using advanced modern technologies like IoT sensors and predictive maintenance software can assist in keeping track of the lift's problem in real-time, allowing timely treatments before concerns escalate. In addition, supplying continuous training for maintenance personnel on the most up to date sector requirements and ideal techniques is visite site vital for upholding upkeep excellence.

Furthermore, promoting a society of accountability and focus to detail among upkeep groups can further raise upkeep criteria. Encouraging open communication networks for reporting and addressing upkeep problems promptly can assist in preserving a high degree of lift system integrity. Ultimately, by prioritizing and raising maintenance requirements, lift systems can run efficiently and safely for a prolonged period.

Verdict

In conclusion, effective lift repair services need aggressive upkeep strategies, troubleshooting methods, and improved repair service abilities. By attending to common challenges and elevating maintenance standards, maintenance specialists can effectively ensure the smooth operation of lifts - Lift Maintenance Repair. Implementing these expert understandings can bring about boosted performance, minimized downtime, and boosted security for both passengers and equipmentIn the realm of lift fixing and upkeep, discovering the approaches that lead to efficient and effective service is similar to understanding a complicated puzzle.Another widespread difficulty in lift repairs is the absence of appropriate maintenance documents. By taking on an aggressive technique to maintenance, structure managers and lift upkeep groups can address possible concerns before they intensify into pricey repair services or downtime.In conclusion, effective lift fixings need proactive upkeep techniques, troubleshooting methods, and enhanced repair abilities. By raising and addressing typical difficulties upkeep requirements, upkeep professionals can properly guarantee the smooth procedure of lifts.

Report this wiki page